Milling with large tool overhangs is practiced in diverse manufacturing processes and is influenced by tool

configuration or work holding fixtures. Milling deep cavities characterized by shoulders, steep walls, wide

edges, and undercuts are typical applications that require tools with large overhangs. An increased tool

overhang reduces tool rigidity which affects machining stability. The outcome is pronounced by vibrations,

poor surface finish, and decreased tool life.

The integral-body design of a long-reach tool provides maximum rigidity solutions. This design concept has

found limited applications due to significant production costs and a high risk of functional loss. For

example, insert breakage can cause damage to the tool body, which may cause great loss when using expensive

tools.

Tool design assemblies are common and used to avoid possible tool breakage. A long-reach tool comprises a

regular-sized milling cutter and a toolholder that mounts the cutter. If need be, the toolholder itself is a

modular assembly and includes standard elements, such as a base unit for machine spindles, extensions,

reducers, and more. The assembly tool principle has important advantages such as versatility, optimized tool

configuration, and effective customization. If the cutter is damaged, it can be replaced easily, while other

assembly elements remain in their working state.

The assembly leads to a loss of tool rigidity, which may influence the tool's dynamic performance compared

to an integral body. The assembly principle enables using tool holders with vibration-dampening capabilities

that significantly improve the assembly's dynamic response. In this case, the cutting conditions should

often be reduced to eliminate vibration and noise that causes decreased productivity.

The performance of indexable milling is improved by factors such as chip-splitting cutting edges, unequal

angular pitches, and a different cutting-edge inclination These attributes relate to cutting geometry and

are associated with the tool itself.

Reducing the weight of the cutter body contributes to better dynamic stability. However, weight reduction

should not impair the strength characteristics of the tool. Steel is the traditional material from which

tools are made. Titanium can be used to replace steel and possesses lower density, yet is characterized by

high strength. Titanium also features excellent corrosion resistance with anti-wear properties being an

important factor for the prolonged tool life of the cutter body. Compared to steel, titanium is

characterized by poor machinability, which inevitably leads to increased manufacturing costs. A tool body

design with cavities will reduce the mass of the cutter yet will increase its manufacturing costs.

Modern production technologies enable solutions to overcome these obstacles. Additive manufacturing (AM)

provides an effective method to achieve the complex configuration of a cutter body while minimizing

machining operations. 3D printing facilitates the production of titanium made tools while assuring

sustainability. Leading cutting tool manufacturers have adopted AM processes to produce milling cutters

intended for machining with large overhangs. It is becoming more common to design lightweight indexable

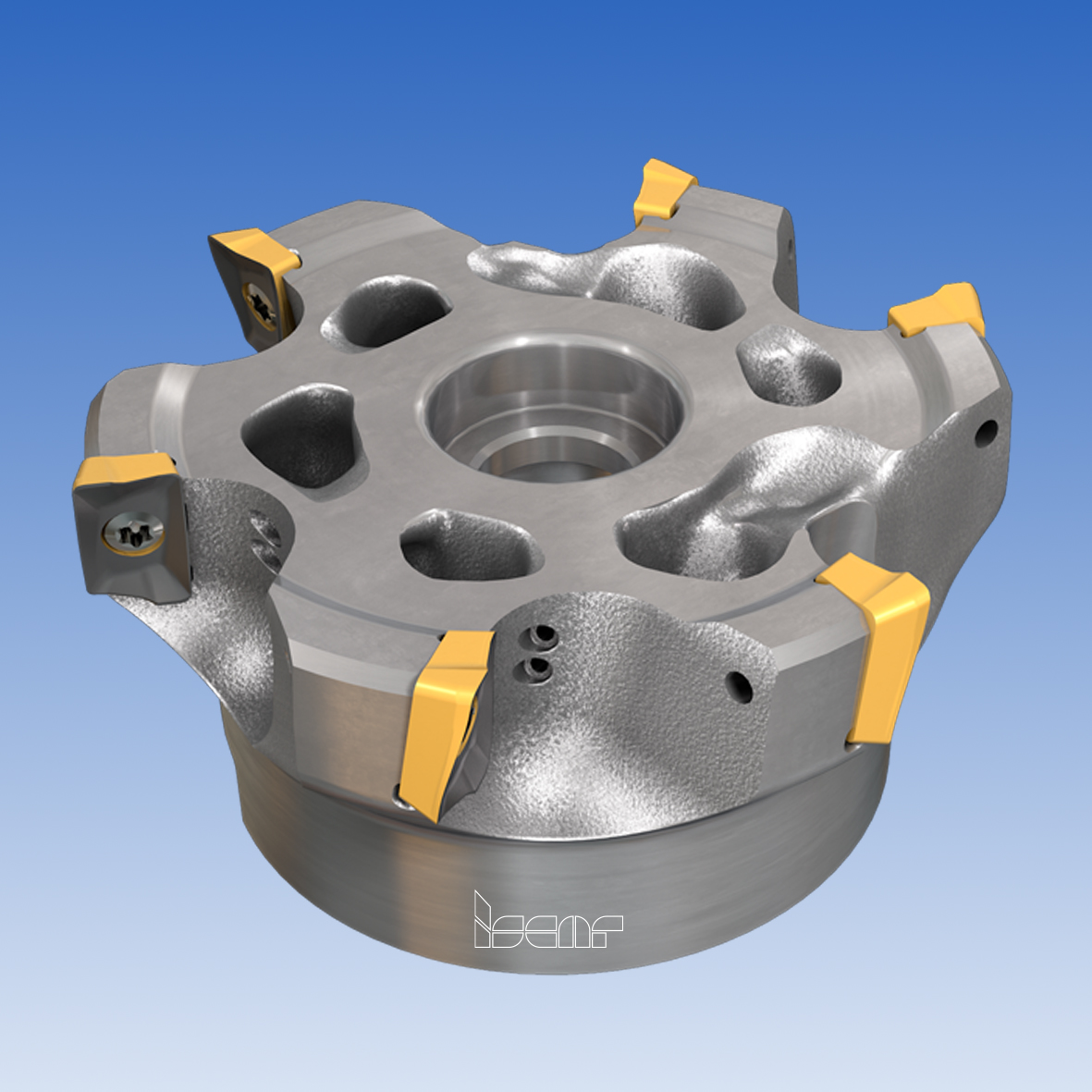

mills with titanium bodies using additive manufacturing. One of the new shell mill designs was recently

introduced by ISCAR (Fig. 1). The mills expand the product range of HELI2000 90° milling cutters where

indexable inserts with helical cutting edges are mounted. The implementation of lightweight titanium body

cutters with helical-edged inserts is symbolic of ISCAR, renowned for its original and innovative milling

solutions.

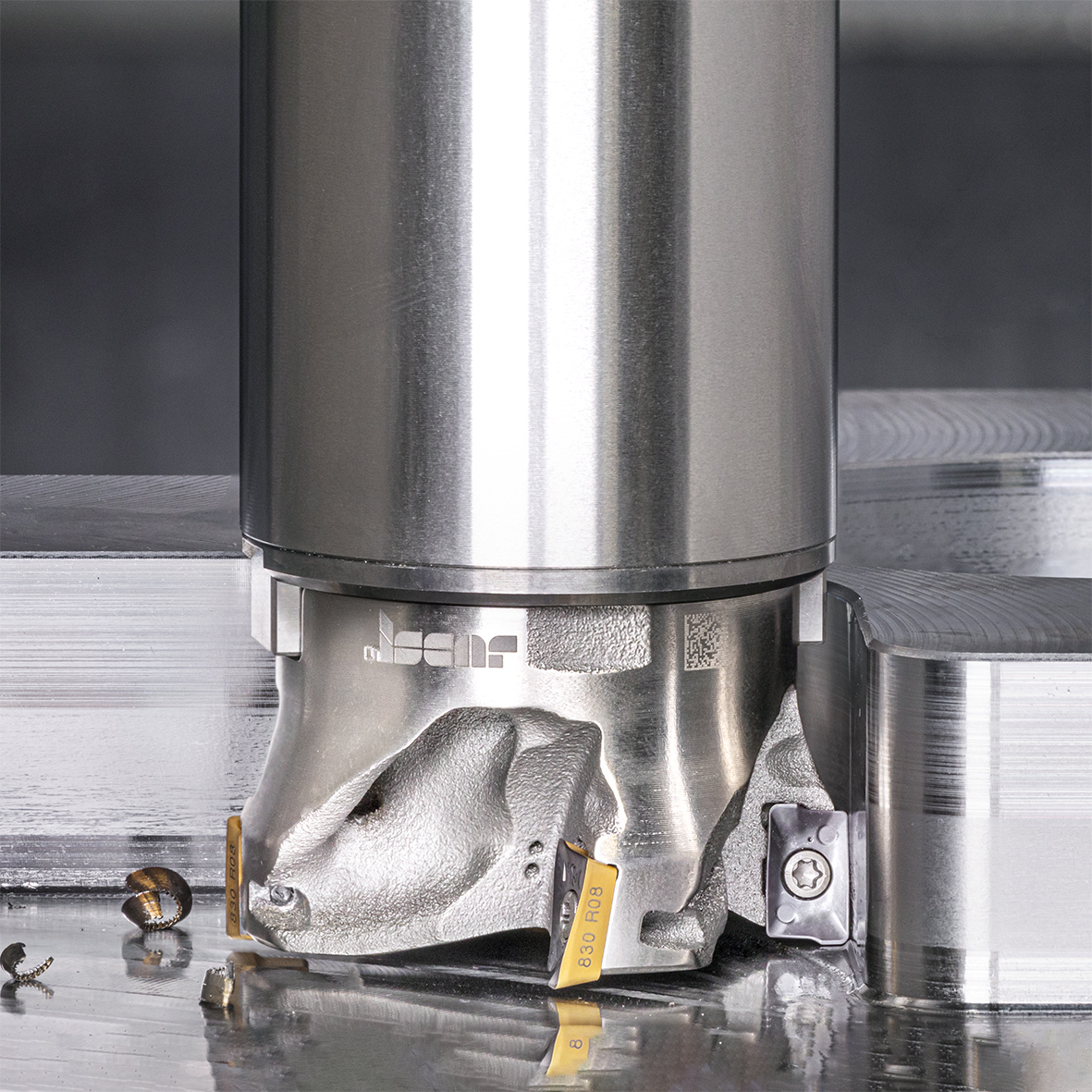

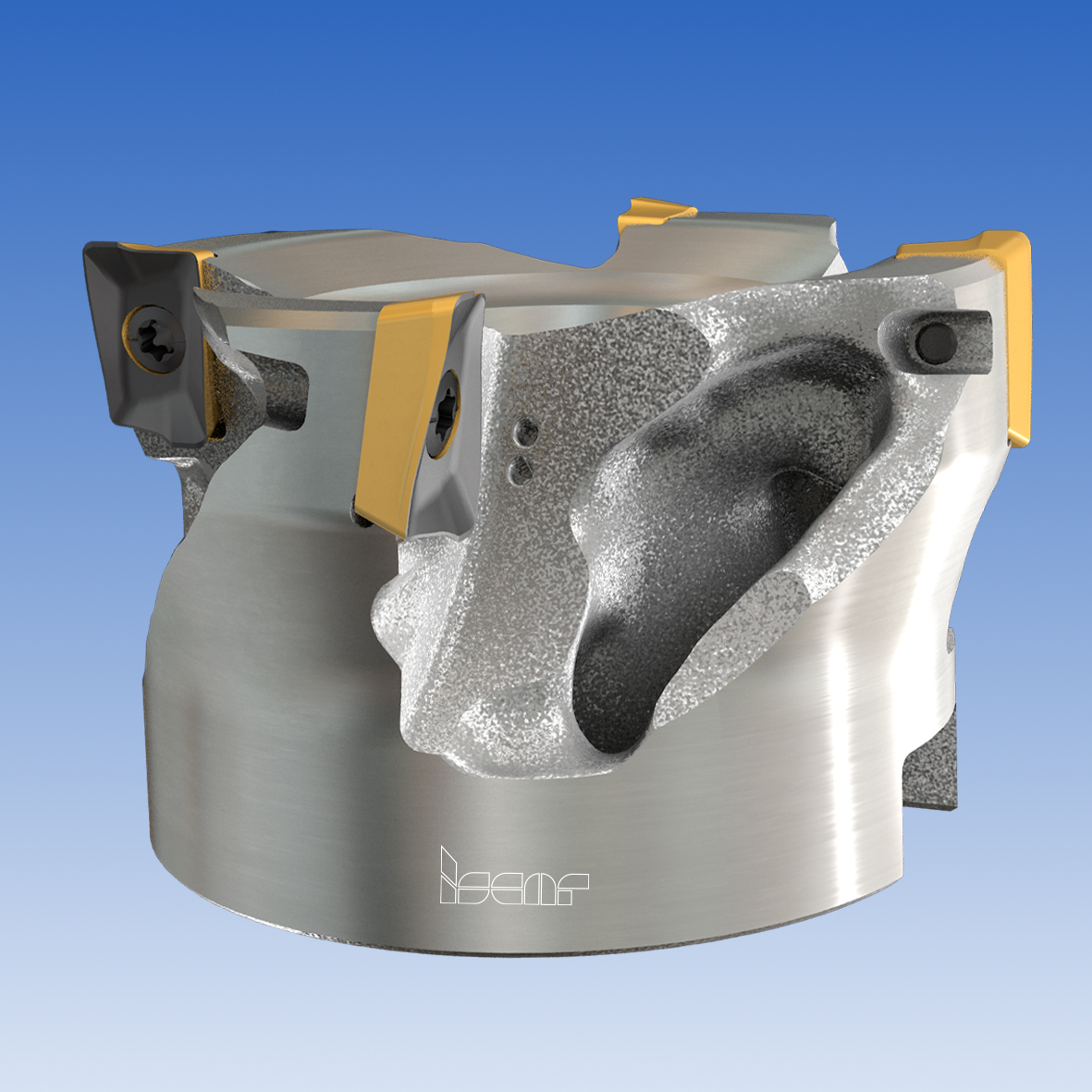

The shell mill body is shaped by the use of selective laser melting (SLM) techniques, being one of the 3D

printing techniques. As a result, tool body elements such as chip gullets and weight-reduction cavities

feature sophisticated forms, uncommon for machining metals. (Fig. 2, 3). Additive manufacturing technologies

enable maximum use of computational fluid dynamics for optimizing the profile of inner channels to ensure

efficient pinpointed coolant through the cutter body. Traditional machining processes have limitations in

shaping the channels, while AM capabilities provide endless options.

The mill design concept also utilizes the unequal angular pitch principle to improve the vibration

resistance of the cutter.

The new design based on the combination of untypical body material with AM advantages has brought robust

lightweight indexable shell mills intended for long-reach machining applications. The new tool provides

stable cutting with high overhangs, which ensures increased productivity and tool life. At the initial

stage, ISCAR introduces titanium-body shell mills in diameters of 50 and 63 mm (metric product line), or

2.00 inches. To improve results and to achieve an excellent surface finish, it is recommended to mount the

milling cutter on tool holders with an anti-vibration mechanism, such ISCAR's WHISPER LINE adaptors.